Shenzhen Wesort Optoelectronics Co., Ltd.

Address:Building 29, Longwangmiao Industrial Zone, Fuyong street, Bao'an District, Shenzhen, Guangdong Province, China.

Phone:+86 181 2370 6862

| MODEL | 6SXZ-204 | CAPACITY (KG/H) | 1500-2400 |

| ACCURAXY (%) | ≥99 | POWER (KW) | 2.0-2.4 |

| AIR PRESSURE (MPA) | 0.4-0.6 | GAS CONSUMPTION (L/MIN) | <1500 |

| WEIGHT (KG) | 440 | DIMENSIONS(MM) | 1616*1563*1652 |

Note : The above processing capacityis calculated based on the raw material with an impurity content of 5% wheat

| MODEL | 6SXZ-204 | CAPACITY (KG/H) | 1500-2400 |

| ACCURAXY (%) | ≥99 | POWER (KW) | 2.0-2.4 |

| AIR PRESSURE (MPA) | 0.4-0.6 | GAS CONSUMPTION (L/MIN) | <1500 |

| WEIGHT (KG) | 440 | DIMENSIONS(MM) | 1616*1563*1652 |

Note : The above processing capacityis calculated based on the raw material with an impurity content of 5% wheat

A Cereals Color Sorting Machine is an advanced piece of equipment designed to sort cereals based on their color and quality, widely used in grain processing industries to ensure high standards of product purity and uniformity. This machine uses optical technology to detect and remove defective, discolored, or foreign materials from cereals like rice, wheat, corn, barley, oats, and more.

### Key Components and Features of a Cereals Color Sorting Machine:

1. Optical Cameras & Sensors: Equipped with high-resolution cameras (RGB or infrared) and sensors that capture even the smallest color differences in cereal grains.

2. LED Lighting System: Illuminates the grains to enhance color detection, enabling precise sorting.

3. High-speed Ejectors: The machine has fast and accurate air ejectors that instantly remove any defective or unwanted grains from the production line.

4. Software Algorithms: Advanced image processing algorithms that analyze each grain's color, shape, and size to make sorting decisions quickly.

5. Customizable Sorting Parameters: Operators can adjust the machine settings to meet the specific requirements of different cereal types (e.g., rice, wheat, corn) and processing goals (e.g., sorting out damaged grains, stones, foreign objects).

6. User-friendly Interface: The machine typically has a touchscreen control panel that allows for easy monitoring and adjustments.

7. Multi-stage Sorting: Some machines offer multi-stage sorting, allowing for several rounds of sorting to improve accuracy.

### Benefits of a Cereals Color Sorting Machine:

- Enhanced Quality: Ensures consistent quality by eliminating defective or discolored cereals and removing contaminants like stones, plastic, and metal.

- Increased Efficiency: Automates the sorting process, allowing for faster and more precise sorting than manual methods.

- Reduced Labor Costs: Minimal human intervention is required, as the machine operates autonomously once programmed.

- Product Safety: By removing foreign objects and contaminants, the machine helps improve food safety and compliance with industry standards.

- Waste Reduction: Minimizes the rejection of good cereals by accurately targeting only defective grains.

### Applications:

- Rice Processing Plants

- Wheat and Corn Mills

- Barley and Oats Production

- Cereal Grain Processing for Food and Beverage Industries

Cereal color sorters are vital in ensuring that only the best quality cereals make it to the market, enhancing product value, safety, and consumer satisfaction.

A Cereals Color Sorting Machine is an advanced piece of equipment designed to sort cereals based on their color and quality, widely used in grain processing industries to ensure high standards of product purity and uniformity. This machine uses optical technology to detect and remove defective, discolored, or foreign materials from cereals like rice, wheat, corn, barley, oats, and more.

### Key Components and Features of a Cereals Color Sorting Machine:

1. Optical Cameras & Sensors: Equipped with high-resolution cameras (RGB or infrared) and sensors that capture even the smallest color differences in cereal grains.

2. LED Lighting System: Illuminates the grains to enhance color detection, enabling precise sorting.

3. High-speed Ejectors: The machine has fast and accurate air ejectors that instantly remove any defective or unwanted grains from the production line.

4. Software Algorithms: Advanced image processing algorithms that analyze each grain's color, shape, and size to make sorting decisions quickly.

5. Customizable Sorting Parameters: Operators can adjust the machine settings to meet the specific requirements of different cereal types (e.g., rice, wheat, corn) and processing goals (e.g., sorting out damaged grains, stones, foreign objects).

6. User-friendly Interface: The machine typically has a touchscreen control panel that allows for easy monitoring and adjustments.

7. Multi-stage Sorting: Some machines offer multi-stage sorting, allowing for several rounds of sorting to improve accuracy.

### Benefits of a Cereals Color Sorting Machine:

- Enhanced Quality: Ensures consistent quality by eliminating defective or discolored cereals and removing contaminants like stones, plastic, and metal.

- Increased Efficiency: Automates the sorting process, allowing for faster and more precise sorting than manual methods.

- Reduced Labor Costs: Minimal human intervention is required, as the machine operates autonomously once programmed.

- Product Safety: By removing foreign objects and contaminants, the machine helps improve food safety and compliance with industry standards.

- Waste Reduction: Minimizes the rejection of good cereals by accurately targeting only defective grains.

### Applications:

- Rice Processing Plants

- Wheat and Corn Mills

- Barley and Oats Production

- Cereal Grain Processing for Food and Beverage Industries

Cereal color sorters are vital in ensuring that only the best quality cereals make it to the market, enhancing product value, safety, and consumer satisfaction.

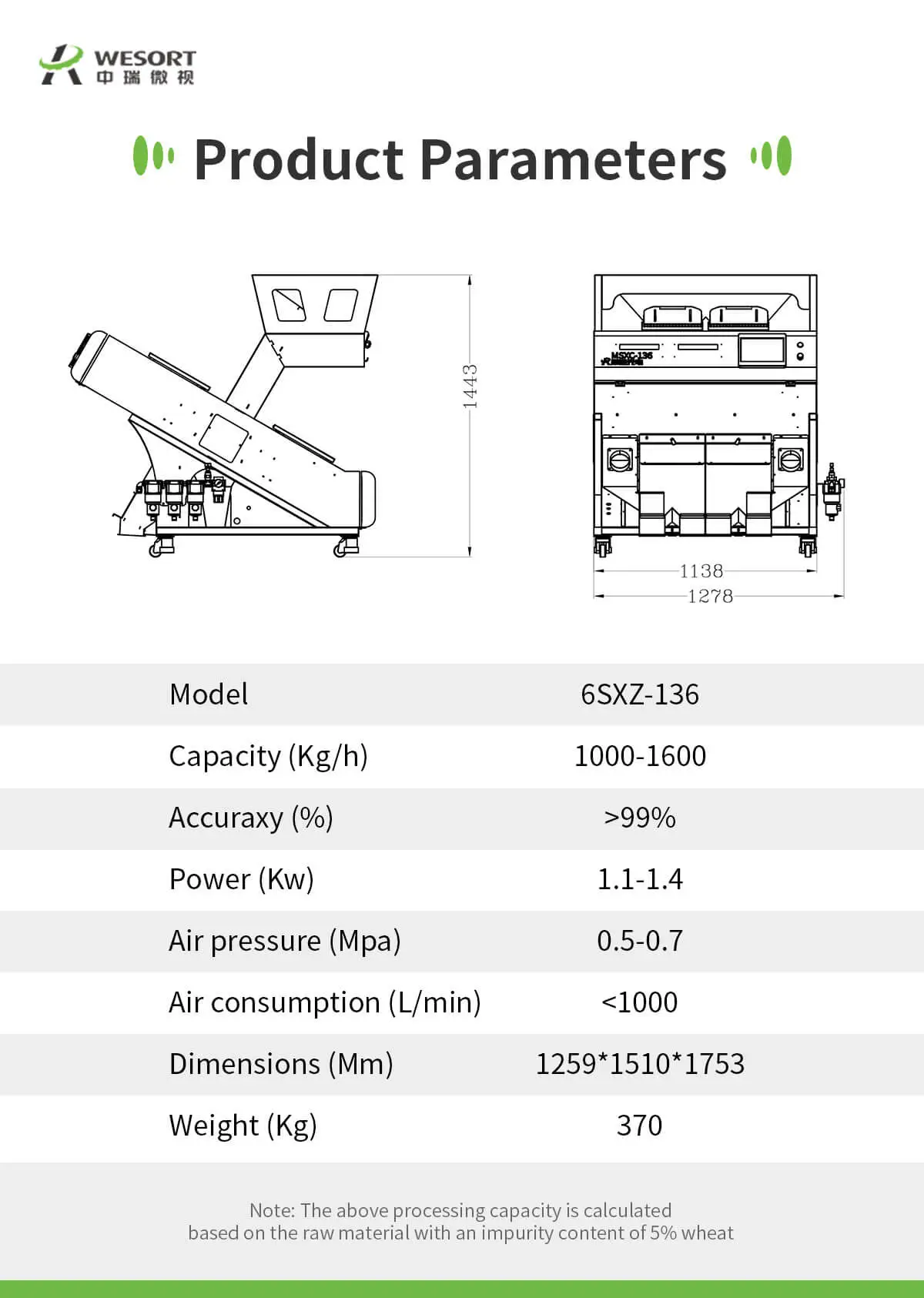

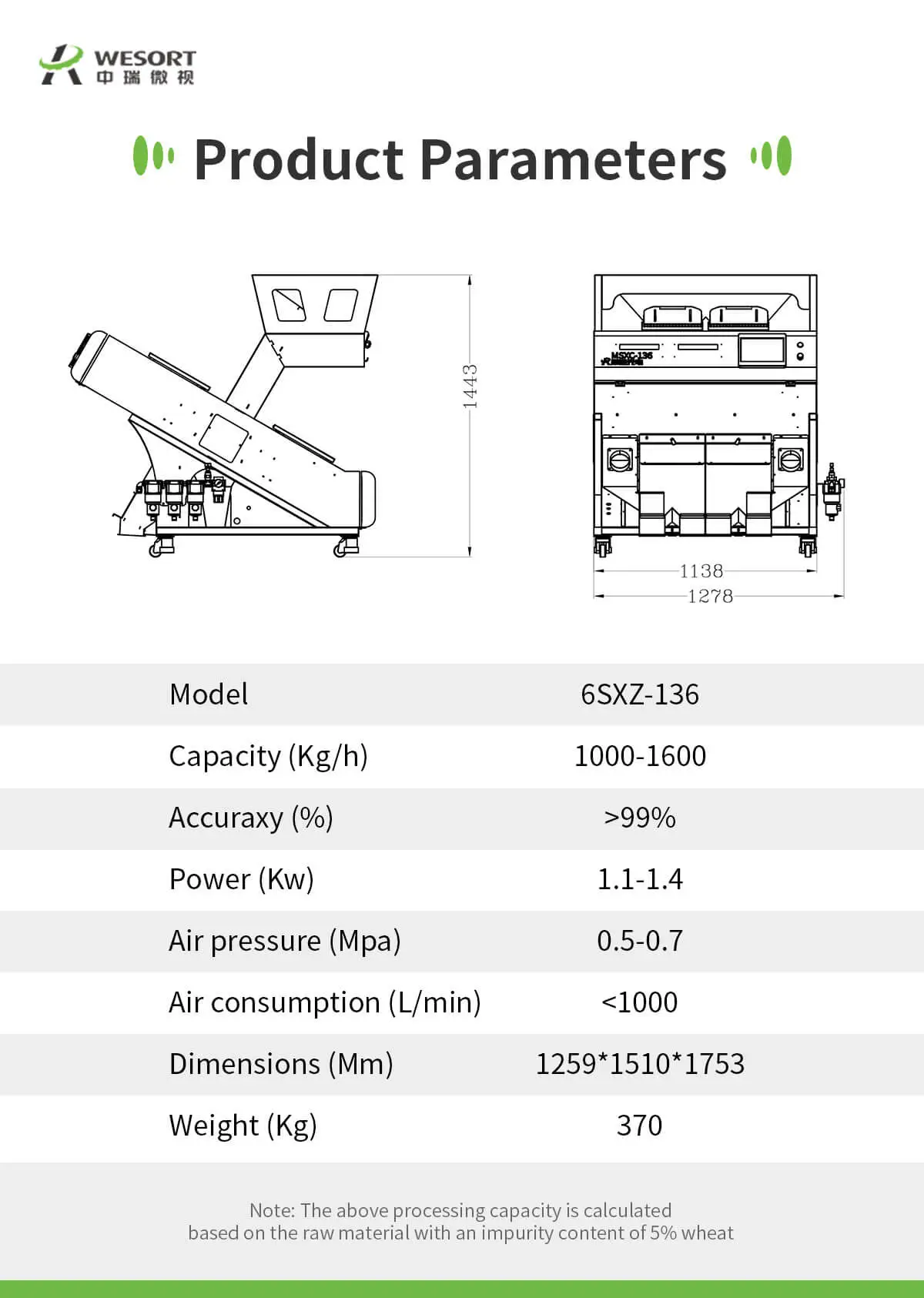

MODEL 6SXZ-136 CAPACITY (KG/H) 1000-1600 ACCURAXY (%) ≥99 POWER (KW) 1.4-1.8 AIR PRESSURE (MPA) 0.4-0.6 GAS CONSUMPTION (L/MIN) <1000 WEIGHT (KG) 370 DIMENSIONS(MM) 1278*1566*1443 Note : The above processing capacityis calculated based on the raw mat...

Product model 6SXZ-136 Capacity (KG/H) 100-200 Air source pressure(Mpa) 0.4-0.6 Power source(mpa) 220v 50hz Power (w) 1.4-1.8 Air consumption (L/min) <1000 Weight(KG) 370 Size (mm) 1278*1566*1443

Product model 6SXZ-204 Capacity (KG/H) 150-300 Air source pressure(Mpa) 0.4-0.6 Power source(mpa) 220v 50hz Power (w) 2.0-2.4 Air consumption (L/min) <1500 Weight(KG) 440 Size (mm) 1616*1563*1652

The peanut color sorter uses advanced optical recognition technology and intelligent algorithms. It can quickly and accurately identify the different-colored particles, impurities and defective peanuts in the peanuts. Whether it is peanuts that have ...

Corn Color Sorter | High-Precision Optical Sorting Machine Product Description The WESORT Corn Color Sorter is a high-end optical sorting machine designed to deliver superior grain quality with advanced RGB CCD technology. Built for corn and multipur...

A multi-function wheat color sorter machine is designed to separate wheat grains based on color differences, helping to remove impurities and ensure higher quality in the final product. This color sorter is common equipment for flour grinding. It...

MODEL 6SXZ-90 CAPACITY (KG/H) 600-900 ACCURAXY (%) ≥99 POWER (KW) 1.0-1.4 AIR PRESSURE (MPA) 0.4-0.6 GAS CONSUMPTION (L/MIN) <750 WEIGHT (KG) 310 DIMENSIONS(MM) 990*1538*1996 Note : The above processing capacityis calculated based on the raw material...

MODEL 6SXZ-136 CAPACITY (KG/H) 1000-1600 ACCURAXY (%) ≥99 POWER (KW) 1.4-1.8 AIR PRESSURE (MPA) 0.4-0.6 GAS CONSUMPTION (L/MIN) <1000 WEIGHT (KG) 370 DIMENSIONS(MM) 1278*1566*1443 Note : The above processing capacityis calculated based on the raw mat...

Product model 6SXZ-136 Capacity (KG/H) 100-200 Air source pressure(Mpa) 0.4-0.6 Power source(mpa) 220v 50hz Power (w) 1.4-1.8 Air consumption (L/min) <1000 Weight(KG) 370 Size (mm) 1278*1566*1443

Product model 6SXZ-204 Capacity (KG/H) 150-300 Air source pressure(Mpa) 0.4-0.6 Power source(mpa) 220v 50hz Power (w) 2.0-2.4 Air consumption (L/min) <1500 Weight(KG) 440 Size (mm) 1616*1563*1652

The peanut color sorter uses advanced optical recognition technology and intelligent algorithms. It can quickly and accurately identify the different-colored particles, impurities and defective peanuts in the peanuts. Whether it is peanuts that have ...

Corn Color Sorter | High-Precision Optical Sorting Machine Product Description The WESORT Corn Color Sorter is a high-end optical sorting machine designed to deliver superior grain quality with advanced RGB CCD technology. Built for corn and multipur...

A multi-function wheat color sorter machine is designed to separate wheat grains based on color differences, helping to remove impurities and ensure higher quality in the final product. This color sorter is common equipment for flour grinding. It...

MODEL 6SXZ-90 CAPACITY (KG/H) 600-900 ACCURAXY (%) ≥99 POWER (KW) 1.0-1.4 AIR PRESSURE (MPA) 0.4-0.6 GAS CONSUMPTION (L/MIN) <750 WEIGHT (KG) 310 DIMENSIONS(MM) 990*1538*1996 Note : The above processing capacityis calculated based on the raw material...

MODEL 6SXZ-136 CAPACITY (KG/H) 1000-1600 ACCURAXY (%) ≥99 POWER (KW) 1.4-1.8 AIR PRESSURE (MPA) 0.4-0.6 GAS CONSUMPTION (L/MIN) <1000 WEIGHT (KG) 370 DIMENSIONS(MM) 1278*1566*1443 Note : The above processing capacityis calculated based on the raw mat...