Shenzhen Wesort Optoelectronics Co., Ltd.

Address:Building 29, Longwangmiao Industrial Zone, Fuyong street, Bao'an District, Shenzhen, Guangdong Province, China.

Phone:+86 181 2370 6862

The color sorter is a device that uses photoelectric technology to automatically sort out the heterochromatic particles in granular materials based on the color differences of the materials. It is widely used in many fields and is widely used in rice, cereals, nuts, industrial and other industries.

It is especially suitable for rice, tea, sesame, beans, melon seeds, peanuts, cottonseed, wolfberry, pepper, seeds, dried shrimps, etc. The effect of sorting impurities and special materials such as raisins, traditional Chinese medicine, glass, plastics, cinders, ores, and special materials is very remarkable and has reached the international leading level.

First, connect the power supply, turn on the tablet, touch the touch screen to start color selection; then pour the material to be selected for color into the vibrating feeding hopper, and use the high-frequency vibration of the feeder to shake the material and drop it into the material distribution slot; when the material falls into the dividing When selecting a box, two multi-megapixel cameras at the front and rear will comprehensively take high-frequency photos of each material, so as not to miss any blind spots.

The pictures will be compared with qualified materials through spectral analysis, and it will be found that materials that are inconsistent with qualified products, have different colors, and the air valve will Unqualified materials are blown into the overflow outlet, and qualified materials fall into the qualified material outlet along the set route.

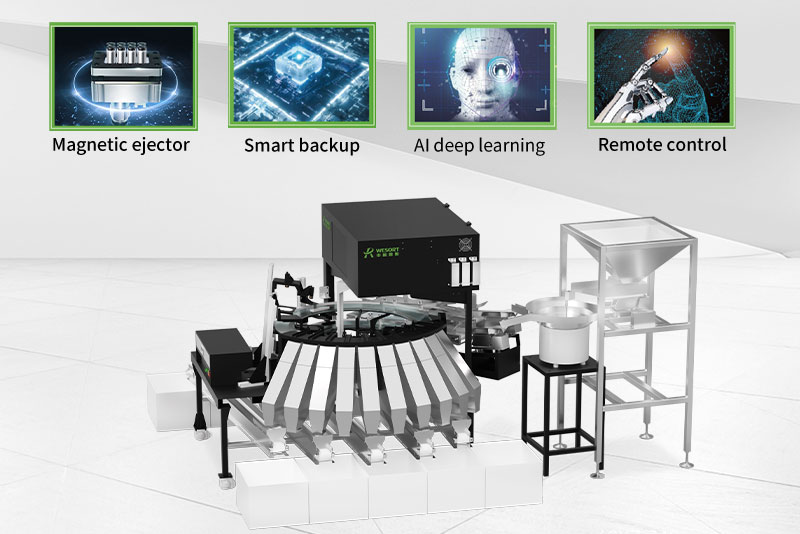

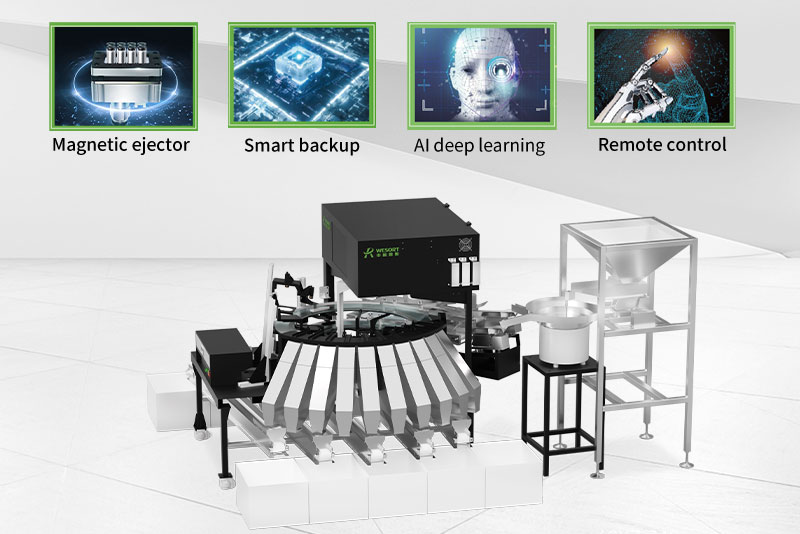

The main components of the color sorter are feed hopper, vibrating feeder, chute, light source, background plate, CCD lens, discharge hopper, nozzle, air compressor, air storage tank, and filter.

1.Feeding system

It consists of a hopper, a vibrating feeder and a chute. The raw materials enter the vibrating feeder from the feeding hopper, and are automatically arranged into a series of continuous streamlines through the vibration and guiding mechanism, and after being accelerated by the chute, they drop to the detection area at a uniform speed. To ensure that the materials are clearly present in the sorting cabinet. In addition to the function of providing raw materials, the feeding system also controls the production capacity of the color sorter. Sorting per unit time can be realized.

2.Photoelectric system

The photoelectric system is the core part of the color sorter, which is mainly composed of LED light source, background board, CCD lens and related auxiliary equipment. The light source provides stable and uniform illumination for the tested material and the background board. The CCD lens converts the reflected light of the tested material into electrical signals in the detection area. The background board provides a reference signal for the electronic control system.

3.Sorting system

The sorting system consists of sorting cabinets, nozzles, air supply and other accessories. Experiments have proved that the nozzle spacing and the number of nozzles are one of the key factors that affect the accuracy of the color sorter.

4.Cleaning system

The cleaning system is composed of cylinders, glass cleaning brushes and other components. Because some items contain dust and other impurities, they may stick to the glass during the color classification process. Once dust and impurities adhere to the car window glass, the photoelectric system may cause interlocking problems such as false detection, thereby affecting the color selection accuracy and carry-over rate.

5.Operating system

The large-screen wide-angle touch screen is used to preset a variety of color selection modes for customers. And establish a friendly man-machine interface, which can be adjusted conveniently and quickly according to the specific conditions of the material.

Compared with manual sorting, it saves labor, time, high efficiency and low processing costs. Improve the quality and social and economic benefits of the selected products.

Although manufacturers produce different types of color sorters, most belong to the following three main types:

1.Chute color sorters

The product chutes of chute sorters are equipped with rows of optical sensors that can operate simultaneously to ensure comprehensive and accurate detection. These machines can quickly sort large quantities of materials and are ideal for high-capacity production lines.

2.Belt color sorters

This type of sorter uses a conveyor belt to transport materials through a single optical sensor. Because the objects do not move much, they are not easily damaged, so many companies use this type of sorter to sort fragile items.

3.Optical color sorters

Optical color sorting uses lasers or cameras to automatically sort bulk products. This non-destructive machine can identify the structure, shape, defect size and chemical composition of the product with a detection rate of 100%.

WESORT color sorters have higher quality color sorting products, and the products have a great advantage in peer competition, which helps to enhance the brand and reputation. Help customers solve quality problems and help customers grow bigger and stronger.

The color sorter is a device that uses photoelectric technology to automatically sort out the heterochromatic particles in granular materials based on the color differences of the materials. It is widely used in many fields and is widely used in rice, cereals, nuts, industrial and other industries.

It is especially suitable for rice, tea, sesame, beans, melon seeds, peanuts, cottonseed, wolfberry, pepper, seeds, dried shrimps, etc. The effect of sorting impurities and special materials such as raisins, traditional Chinese medicine, glass, plastics, cinders, ores, and special materials is very remarkable and has reached the international leading level.

First, connect the power supply, turn on the tablet, touch the touch screen to start color selection; then pour the material to be selected for color into the vibrating feeding hopper, and use the high-frequency vibration of the feeder to shake the material and drop it into the material distribution slot; when the material falls into the dividing When selecting a box, two multi-megapixel cameras at the front and rear will comprehensively take high-frequency photos of each material, so as not to miss any blind spots.

The pictures will be compared with qualified materials through spectral analysis, and it will be found that materials that are inconsistent with qualified products, have different colors, and the air valve will Unqualified materials are blown into the overflow outlet, and qualified materials fall into the qualified material outlet along the set route.

The main components of the color sorter are feed hopper, vibrating feeder, chute, light source, background plate, CCD lens, discharge hopper, nozzle, air compressor, air storage tank, and filter.

1.Feeding system

It consists of a hopper, a vibrating feeder and a chute. The raw materials enter the vibrating feeder from the feeding hopper, and are automatically arranged into a series of continuous streamlines through the vibration and guiding mechanism, and after being accelerated by the chute, they drop to the detection area at a uniform speed. To ensure that the materials are clearly present in the sorting cabinet. In addition to the function of providing raw materials, the feeding system also controls the production capacity of the color sorter. Sorting per unit time can be realized.

2.Photoelectric system

The photoelectric system is the core part of the color sorter, which is mainly composed of LED light source, background board, CCD lens and related auxiliary equipment. The light source provides stable and uniform illumination for the tested material and the background board. The CCD lens converts the reflected light of the tested material into electrical signals in the detection area. The background board provides a reference signal for the electronic control system.

3.Sorting system

The sorting system consists of sorting cabinets, nozzles, air supply and other accessories. Experiments have proved that the nozzle spacing and the number of nozzles are one of the key factors that affect the accuracy of the color sorter.

4.Cleaning system

The cleaning system is composed of cylinders, glass cleaning brushes and other components. Because some items contain dust and other impurities, they may stick to the glass during the color classification process. Once dust and impurities adhere to the car window glass, the photoelectric system may cause interlocking problems such as false detection, thereby affecting the color selection accuracy and carry-over rate.

5.Operating system

The large-screen wide-angle touch screen is used to preset a variety of color selection modes for customers. And establish a friendly man-machine interface, which can be adjusted conveniently and quickly according to the specific conditions of the material.

Compared with manual sorting, it saves labor, time, high efficiency and low processing costs. Improve the quality and social and economic benefits of the selected products.

Although manufacturers produce different types of color sorters, most belong to the following three main types:

1.Chute color sorters

The product chutes of chute sorters are equipped with rows of optical sensors that can operate simultaneously to ensure comprehensive and accurate detection. These machines can quickly sort large quantities of materials and are ideal for high-capacity production lines.

2.Belt color sorters

This type of sorter uses a conveyor belt to transport materials through a single optical sensor. Because the objects do not move much, they are not easily damaged, so many companies use this type of sorter to sort fragile items.

3.Optical color sorters

Optical color sorting uses lasers or cameras to automatically sort bulk products. This non-destructive machine can identify the structure, shape, defect size and chemical composition of the product with a detection rate of 100%.

WESORT color sorters have higher quality color sorting products, and the products have a great advantage in peer competition, which helps to enhance the brand and reputation. Help customers solve quality problems and help customers grow bigger and stronger.

In modern agriculture, food processing, and recycling, quality control plays a vital role. This is where an optical sorter comes in. Many buyers often ask: What is an optical sorter? What does it do? How much does it cost? And how is WESORT optical...

In the coffee industry, the quality of the final cup often depends on the smallest details during processing. One crucial step is removing defective beans, foreign materials, and color inconsistencies. This is where a coffee bean color sorter plays...

Coffee processing is a complex and meticulous task that involves several stages to transform raw coffee cherries into the high-quality beans we enjoy in our morning brew. One crucial step in this process is the sorting of coffee beans based on thei...

In the world of walnut processing, even the smallest imperfection can significantly impact product quality, market price, and brand reputation. Mold, insect damage, broken pieces, or inconsistent color are common defects that reduce the value of wa...

From green bean exporters to specialty coffee roasters, every producer faces the same challenge: how to remove defects efficiently while protecting valuable beans. Problems such as mold, fermentation damage, insect bites, black beans, broken beans,...

To meet the growing demand for premium and specialty coffee, sorting accuracy must go beyond traditional color-based systems. The QuadEye 360 AI Coffee Bean Sorter, developed by WESORT, represents the next generation of intelligent coffee bean so...

Dear friend, If you are attending World of Coffee Dubai 2026. we would like to invite you to visit WESORT. We will showcase our QuadEye 360 AI Coffee Bean Sorter, featuring 360° four-side inspection, AI deep learning models, near-zero breakage,...

Meta Description: Looking for the top hazelnut sorting machine manufacturer? WESORT offers advanced hazelnut color sorters with AI deep learning to efficiently remove defects, pests, and foreign materials. Boost your hazelnut processing efficienc...

With the growing popularity of specialty coffee, the purity of coffee beans determines the aroma and taste of a cup of coffee. Achieving 99.9% purity requires high-performance coffee bean sorting equipment. Among Chinese coffee bean color sorter ma...

What's the most vexing issue in the hazelnut industry chain? It's not yield, but quality. Defects like mold, wrinkled skin, and foreign matter not only reduce product value but can also put export orders at risk. The solution isn't to increase the ...

Every hazelnut tells a story—about the soil it grew in, the care during harvest, and the precision of its processing. Yet between farm and final product, hidden defects like mold, insect damage, and discoloration can turn premium hazelnuts into cos...

Plastic waste recycling is one of the most pressing challenges in today’s sustainability-driven world. Proper plastic sorting ensures high-quality recycled materials, reduces environmental impact, and improves profitability for recycling businesses...

In the plastic recycling industry, purity and efficiency directly determine profitability. As global demand for recycled plastics increases, manufacturers need advanced solutions to separate impurities, improve yield, and ensure consistent product ...

In Mexico, coffee is more than just a drink — it’s a culture, a tradition, and a vital industry. Yet, challenges like impurities, pest damage, and uneven coloration often diminish the value of even the most carefully cultivated beans. At EXPO CAFÉ...

The global demand for hazelnuts continues to rise, driven by the growth of confectionery, bakery, and healthy snack markets. As consumption increases, so does the importance of quality control. Hazelnut processors face mounting pressure to deliver ...

Hazelnuts are widely used in confectionery, bakery, and snacks, where product quality directly affects market value. However, hazelnut processing often faces serious challenges, such as pest infestation, seasonal labor shortages, and inconsistent m...

Hazelnut is the nut of the hazel and therefore includes any of the nuts deriving from species of the genus Corylus, especially the nuts of the species Corylus avellana. It is also known as cobnut or filbert nut according to species. A cob is roughl...

When you enjoy a smooth cup of coffee, you may not realize how much work goes into ensuring its purity and flavor. From harvest to cup, every step matters—and one of the most critical yet often overlooked stages is coffee bean sorting. Common Cof...

Dear Coffee Industry Partners, The Mexican Coffee Shop Expo 2025 is just around the corner—and WESORT , a leader in intelligent sorting technology, will be there to showcase our core solution for coffee processors: Coffee Bean Color Sorters. Mark...

In the plastic pellet production process, color purity often directly determines the product's selling price and market competitiveness. Especially for transparent, white, or light-colored plastic pellets, even tiny black specks can affect the appe...

In modern agriculture, food processing, and recycling, quality control plays a vital role. This is where an optical sorter comes in. Many buyers often ask: What is an optical sorter? What does it do? How much does it cost? And how is WESORT optical...

In the coffee industry, the quality of the final cup often depends on the smallest details during processing. One crucial step is removing defective beans, foreign materials, and color inconsistencies. This is where a coffee bean color sorter plays...

Coffee processing is a complex and meticulous task that involves several stages to transform raw coffee cherries into the high-quality beans we enjoy in our morning brew. One crucial step in this process is the sorting of coffee beans based on thei...

In the world of walnut processing, even the smallest imperfection can significantly impact product quality, market price, and brand reputation. Mold, insect damage, broken pieces, or inconsistent color are common defects that reduce the value of wa...

From green bean exporters to specialty coffee roasters, every producer faces the same challenge: how to remove defects efficiently while protecting valuable beans. Problems such as mold, fermentation damage, insect bites, black beans, broken beans,...

To meet the growing demand for premium and specialty coffee, sorting accuracy must go beyond traditional color-based systems. The QuadEye 360 AI Coffee Bean Sorter, developed by WESORT, represents the next generation of intelligent coffee bean so...

Dear friend, If you are attending World of Coffee Dubai 2026. we would like to invite you to visit WESORT. We will showcase our QuadEye 360 AI Coffee Bean Sorter, featuring 360° four-side inspection, AI deep learning models, near-zero breakage,...

Meta Description: Looking for the top hazelnut sorting machine manufacturer? WESORT offers advanced hazelnut color sorters with AI deep learning to efficiently remove defects, pests, and foreign materials. Boost your hazelnut processing efficienc...