Shenzhen Wesort Optoelectronics Co., Ltd.

Address:Building 29, Longwangmiao Industrial Zone, Fuyong street, Bao'an District, Shenzhen, Guangdong Province, China.

Phone:+86 181 2370 6862

Color sorters are used in food processing, resource recycling, ore mining and other industries, such as coffee beans, nuts and oil crops in the food industry, to separate crops that are discolored, toxic (such as moldy) or have not reached the required maturity. Compared with manual sorting, machines are more efficient and have lower processing costs.

In the world of specialty coffee, quality starts with the bean. From farm to roastery, one essential step shapes flavor, consistency, and value more than most people realize—coffee bean sorting.

Coffee sorting is the process of removing defective or irregular beans from a batch before roasting. These defects might include under-ripe beans, over-fermented cherries, insect damage, black beans, or beans with uneven coloration. Traditionally, sorting is done by hand—tedious, slow, and often inconsistent.

The purpose of sorting is simple yet critical: to ensure that only the highest quality beans move forward in the process. One bad bean can ruin an entire roast. By removing defects early, producers, roasters, and traders can:

1. Improve cup quality

2. Ensure consistent flavor

3. Protect roasting equipment

4. Meet export or buyer standards

For specialty coffee producers, consistent sorting is also key to accessing premium markets.

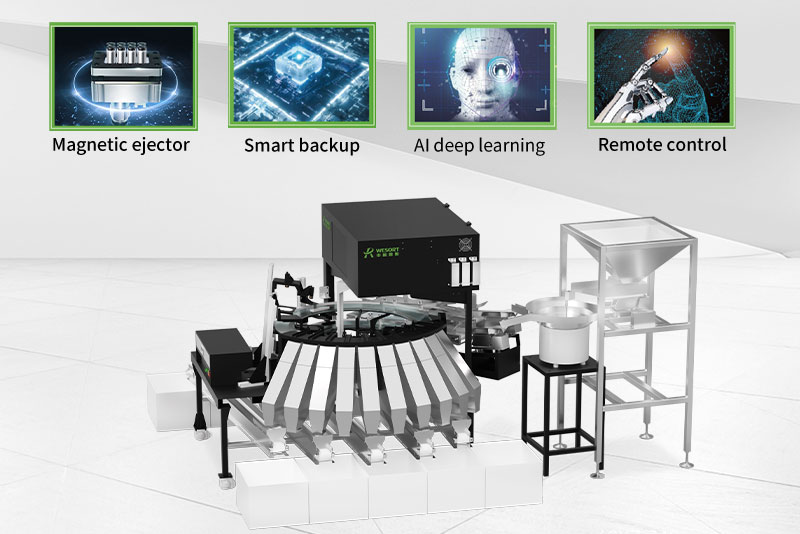

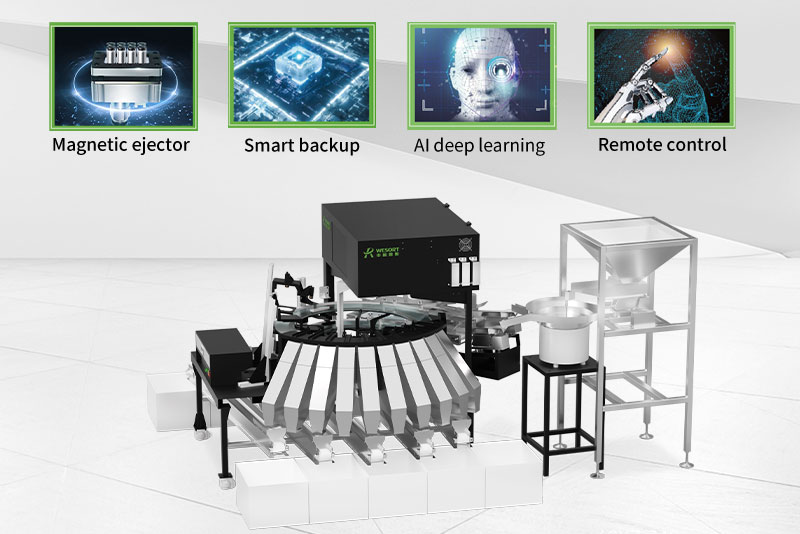

A coffee bean color sorter is an advanced optical machine that uses AI vision and sensors to detect even the smallest defects in color, size, or shape—automatically and at high speed. Instead of spending hours sorting beans by hand, a color sorter can process hundreds of kilograms per hour with over 99% accuracy.

Key benefits of using a coffee sorter machine include:

1. Increased productivity (up to 5x faster than manual sorting)

2. Higher consistency

3. Lower labor costs

4. Better control over roasting results

Sorting is not just a matter of appearance—it protects the integrity of the final product. Defective beans can cause off-flavors, bitterness, or inconsistent roast results. For coffee professionals, sorting:

1. Preserves the true character of origin

2. Builds buyer trust through visible quality

3. Increases market value by improving grading scores

4. Reduces waste by recovering good beans that would otherwise be lost

In today’s competitive coffee market, switching from hand sorting to AI-powered coffee bean sorters is not just an upgrade—it’s a necessity. Whether you're a farmer, trader, or roaster, precision sorting is how great coffee begins.

Ready to sort smarter? Discover how an intelligent coffee sorter can transform your workflow and your cup.

Color sorters are used in food processing, resource recycling, ore mining and other industries, such as coffee beans, nuts and oil crops in the food industry, to separate crops that are discolored, toxic (such as moldy) or have not reached the required maturity. Compared with manual sorting, machines are more efficient and have lower processing costs.

In the world of specialty coffee, quality starts with the bean. From farm to roastery, one essential step shapes flavor, consistency, and value more than most people realize—coffee bean sorting.

Coffee sorting is the process of removing defective or irregular beans from a batch before roasting. These defects might include under-ripe beans, over-fermented cherries, insect damage, black beans, or beans with uneven coloration. Traditionally, sorting is done by hand—tedious, slow, and often inconsistent.

The purpose of sorting is simple yet critical: to ensure that only the highest quality beans move forward in the process. One bad bean can ruin an entire roast. By removing defects early, producers, roasters, and traders can:

1. Improve cup quality

2. Ensure consistent flavor

3. Protect roasting equipment

4. Meet export or buyer standards

For specialty coffee producers, consistent sorting is also key to accessing premium markets.

A coffee bean color sorter is an advanced optical machine that uses AI vision and sensors to detect even the smallest defects in color, size, or shape—automatically and at high speed. Instead of spending hours sorting beans by hand, a color sorter can process hundreds of kilograms per hour with over 99% accuracy.

Key benefits of using a coffee sorter machine include:

1. Increased productivity (up to 5x faster than manual sorting)

2. Higher consistency

3. Lower labor costs

4. Better control over roasting results

Sorting is not just a matter of appearance—it protects the integrity of the final product. Defective beans can cause off-flavors, bitterness, or inconsistent roast results. For coffee professionals, sorting:

1. Preserves the true character of origin

2. Builds buyer trust through visible quality

3. Increases market value by improving grading scores

4. Reduces waste by recovering good beans that would otherwise be lost

In today’s competitive coffee market, switching from hand sorting to AI-powered coffee bean sorters is not just an upgrade—it’s a necessity. Whether you're a farmer, trader, or roaster, precision sorting is how great coffee begins.

Ready to sort smarter? Discover how an intelligent coffee sorter can transform your workflow and your cup.

In modern agriculture, food processing, and recycling, quality control plays a vital role. This is where an optical sorter comes in. Many buyers often ask: What is an optical sorter? What does it do? How much does it cost? And how is WESORT optical...

In the coffee industry, the quality of the final cup often depends on the smallest details during processing. One crucial step is removing defective beans, foreign materials, and color inconsistencies. This is where a coffee bean color sorter plays...

Coffee processing is a complex and meticulous task that involves several stages to transform raw coffee cherries into the high-quality beans we enjoy in our morning brew. One crucial step in this process is the sorting of coffee beans based on thei...

In the world of walnut processing, even the smallest imperfection can significantly impact product quality, market price, and brand reputation. Mold, insect damage, broken pieces, or inconsistent color are common defects that reduce the value of wa...

From green bean exporters to specialty coffee roasters, every producer faces the same challenge: how to remove defects efficiently while protecting valuable beans. Problems such as mold, fermentation damage, insect bites, black beans, broken beans,...

To meet the growing demand for premium and specialty coffee, sorting accuracy must go beyond traditional color-based systems. The QuadEye 360 AI Coffee Bean Sorter, developed by WESORT, represents the next generation of intelligent coffee bean so...

Dear friend, If you are attending World of Coffee Dubai 2026. we would like to invite you to visit WESORT. We will showcase our QuadEye 360 AI Coffee Bean Sorter, featuring 360° four-side inspection, AI deep learning models, near-zero breakage,...

Meta Description: Looking for the top hazelnut sorting machine manufacturer? WESORT offers advanced hazelnut color sorters with AI deep learning to efficiently remove defects, pests, and foreign materials. Boost your hazelnut processing efficienc...

With the growing popularity of specialty coffee, the purity of coffee beans determines the aroma and taste of a cup of coffee. Achieving 99.9% purity requires high-performance coffee bean sorting equipment. Among Chinese coffee bean color sorter ma...

What's the most vexing issue in the hazelnut industry chain? It's not yield, but quality. Defects like mold, wrinkled skin, and foreign matter not only reduce product value but can also put export orders at risk. The solution isn't to increase the ...

Every hazelnut tells a story—about the soil it grew in, the care during harvest, and the precision of its processing. Yet between farm and final product, hidden defects like mold, insect damage, and discoloration can turn premium hazelnuts into cos...

Plastic waste recycling is one of the most pressing challenges in today’s sustainability-driven world. Proper plastic sorting ensures high-quality recycled materials, reduces environmental impact, and improves profitability for recycling businesses...

In the plastic recycling industry, purity and efficiency directly determine profitability. As global demand for recycled plastics increases, manufacturers need advanced solutions to separate impurities, improve yield, and ensure consistent product ...

In Mexico, coffee is more than just a drink — it’s a culture, a tradition, and a vital industry. Yet, challenges like impurities, pest damage, and uneven coloration often diminish the value of even the most carefully cultivated beans. At EXPO CAFÉ...

The global demand for hazelnuts continues to rise, driven by the growth of confectionery, bakery, and healthy snack markets. As consumption increases, so does the importance of quality control. Hazelnut processors face mounting pressure to deliver ...

Hazelnuts are widely used in confectionery, bakery, and snacks, where product quality directly affects market value. However, hazelnut processing often faces serious challenges, such as pest infestation, seasonal labor shortages, and inconsistent m...

Hazelnut is the nut of the hazel and therefore includes any of the nuts deriving from species of the genus Corylus, especially the nuts of the species Corylus avellana. It is also known as cobnut or filbert nut according to species. A cob is roughl...

When you enjoy a smooth cup of coffee, you may not realize how much work goes into ensuring its purity and flavor. From harvest to cup, every step matters—and one of the most critical yet often overlooked stages is coffee bean sorting. Common Cof...

Dear Coffee Industry Partners, The Mexican Coffee Shop Expo 2025 is just around the corner—and WESORT , a leader in intelligent sorting technology, will be there to showcase our core solution for coffee processors: Coffee Bean Color Sorters. Mark...

In the plastic pellet production process, color purity often directly determines the product's selling price and market competitiveness. Especially for transparent, white, or light-colored plastic pellets, even tiny black specks can affect the appe...

In modern agriculture, food processing, and recycling, quality control plays a vital role. This is where an optical sorter comes in. Many buyers often ask: What is an optical sorter? What does it do? How much does it cost? And how is WESORT optical...

In the coffee industry, the quality of the final cup often depends on the smallest details during processing. One crucial step is removing defective beans, foreign materials, and color inconsistencies. This is where a coffee bean color sorter plays...

Coffee processing is a complex and meticulous task that involves several stages to transform raw coffee cherries into the high-quality beans we enjoy in our morning brew. One crucial step in this process is the sorting of coffee beans based on thei...

In the world of walnut processing, even the smallest imperfection can significantly impact product quality, market price, and brand reputation. Mold, insect damage, broken pieces, or inconsistent color are common defects that reduce the value of wa...

From green bean exporters to specialty coffee roasters, every producer faces the same challenge: how to remove defects efficiently while protecting valuable beans. Problems such as mold, fermentation damage, insect bites, black beans, broken beans,...

To meet the growing demand for premium and specialty coffee, sorting accuracy must go beyond traditional color-based systems. The QuadEye 360 AI Coffee Bean Sorter, developed by WESORT, represents the next generation of intelligent coffee bean so...

Dear friend, If you are attending World of Coffee Dubai 2026. we would like to invite you to visit WESORT. We will showcase our QuadEye 360 AI Coffee Bean Sorter, featuring 360° four-side inspection, AI deep learning models, near-zero breakage,...

Meta Description: Looking for the top hazelnut sorting machine manufacturer? WESORT offers advanced hazelnut color sorters with AI deep learning to efficiently remove defects, pests, and foreign materials. Boost your hazelnut processing efficienc...