Shenzhen Wesort Optoelectronics Co., Ltd.

Address:Building 29, Longwangmiao Industrial Zone, Fuyong street, Bao'an District, Shenzhen, Guangdong Province, China.

Phone:+86 181 2370 6862

As a delicious and nutritious nut, the sorting process in the processing of hazelnuts plays a key role in the quality of the product. The following is a detailed introduction to the sorting and processing of hazelnuts:

1. Picking:

When hazelnuts are ripe, workers carefully pick them from the tree and accurately divide them into 5-6 grades according to size. This step lays the foundation for subsequent processing and ensures that hazelnuts of different specifications can be processed in a more suitable way, thereby improving the overall processing efficiency and the stability of product quality.

2. Shelling:

Using professional shelling equipment to perform preliminary shelling of hazelnuts is an important pre-step to remove the hazelnut shell, so that the hazelnut kernels can be separated more conveniently, fully prepared for the subsequent shelling process, and help improve the consistency and efficiency of the entire processing process.

1. Wind sorting and shelling:

With the help of wind sorting technology, the hazelnut shells are effectively removed and the impurity content is strictly controlled between 5-10%. Such a low impurity content can provide more favorable conditions for subsequent color sorting operations, reduce the workload of the color sorter, improve the accuracy and efficiency of sorting, and ensure that the quality of the raw materials entering the next process is more stable and reliable.

2. Shell sorting by color sorter:

WESORT infrared shell kernel sorting machine is very useful in this link. It can further sort the hazelnut shell kernel through advanced optical recognition technology, separate the hazelnut kernel from the shell more accurately, further improve the purity of the hazelnut raw material, and provide high-quality hazelnut kernel raw material for subsequent processing.

3. Color sorter re-selection:

Use WESORT color sorter to accurately remove those hazelnuts that are completely moldy and black. If these moldy hazelnuts are mixed into the subsequent processing links, it will not only affect the quality and taste of the product, but also pose a potential threat to the health of consumers. Therefore, this step is crucial to ensure the quality of hazelnut raw materials.

4. Manual selection:

Although the color sorter has a high sorting accuracy, manual selection is still indispensable. With rich experience and keen observation, workers carefully select hazelnuts and remove those hazelnuts that may be missed by the color sorter, such as those that are slightly damaged, irregular in shape or slightly abnormal in color, to further improve the quality of the raw materials.

1. Water washing and peeling:

The hazelnuts are peeled by gentle water washing. This method can effectively remove the outer skin of the hazelnuts without damaging the hazelnut kernels, making the hazelnuts present a more attractive appearance and taste, and also provides a purer raw material basis for subsequent processing steps.

2. Peeling by color sorter:

Use the WESORT color sorter to screen the peeled hazelnuts to ensure the consistency of the peeling effect and the stability of the quality of the hazelnuts. Through the precise identification and sorting of the color sorter, those hazelnuts with incomplete peeling, uneven color or other impurities can be removed to ensure the high quality of the hazelnuts entering the next process.

1. Drying:

Dry the hazelnuts to reduce their moisture content, extend the shelf life and improve the taste. However, it should be noted that the dried hazelnuts become more fragile, which requires extra care in the subsequent processing and transportation, and take corresponding protective measures, such as using soft containers and cushioning materials to reduce the breakage rate of hazelnuts.

2. Sorting:

Good products (little or no skin):

At this stage, carefully select hazelnuts with little or no skin as good products. These hazelnuts usually have better appearance and taste, which better meet the market demand for high-quality hazelnuts and can bring consumers a better eating experience, thereby improving the market competitiveness of products.

Defective products (with skin, shell, moldy, etc.):

Hazelnuts with serious skin, shell residue, mold, stones or branches are classified as defective. If these defective hazelnuts are mixed into the finished product, it will seriously affect the quality and reputation of the product. Therefore, they must be strictly distinguished to prevent them from entering the market circulation link.

Re-roasting and selection:

For those hazelnuts judged as defective, they are re-roasted and then selected again. Re-roasting can further remove moisture and possible odors from hazelnuts. At the same time, through re-sorting, it can further distinguish unqualified products such as those with severe skin, shell, mold, stone, branches, etc. from relatively good hazelnuts, improve the utilization rate of raw materials, and reduce production costs.

Good products after re-roasting (without skin):

After re-roasting and re-sorting, hazelnuts without skin are selected as good products. Although these hazelnuts have undergone additional processing steps, they still have high quality and can be processed with other good hazelnuts for subsequent processing, ensuring the stability of raw material quality throughout the production process and reducing waste.

In the entire hazelnut processing process, each step is closely linked and indispensable. Through a series of operations such as reasonable rough processing, peeling processing, drying and sorting, and fully combining advanced WESORT color sorting machine technology and meticulous manual sorting, it can ensure the production of high-quality hazelnut products to meet the market demand for high-quality hazelnuts.

As a delicious and nutritious nut, the sorting process in the processing of hazelnuts plays a key role in the quality of the product. The following is a detailed introduction to the sorting and processing of hazelnuts:

1. Picking:

When hazelnuts are ripe, workers carefully pick them from the tree and accurately divide them into 5-6 grades according to size. This step lays the foundation for subsequent processing and ensures that hazelnuts of different specifications can be processed in a more suitable way, thereby improving the overall processing efficiency and the stability of product quality.

2. Shelling:

Using professional shelling equipment to perform preliminary shelling of hazelnuts is an important pre-step to remove the hazelnut shell, so that the hazelnut kernels can be separated more conveniently, fully prepared for the subsequent shelling process, and help improve the consistency and efficiency of the entire processing process.

1. Wind sorting and shelling:

With the help of wind sorting technology, the hazelnut shells are effectively removed and the impurity content is strictly controlled between 5-10%. Such a low impurity content can provide more favorable conditions for subsequent color sorting operations, reduce the workload of the color sorter, improve the accuracy and efficiency of sorting, and ensure that the quality of the raw materials entering the next process is more stable and reliable.

2. Shell sorting by color sorter:

WESORT infrared shell kernel sorting machine is very useful in this link. It can further sort the hazelnut shell kernel through advanced optical recognition technology, separate the hazelnut kernel from the shell more accurately, further improve the purity of the hazelnut raw material, and provide high-quality hazelnut kernel raw material for subsequent processing.

3. Color sorter re-selection:

Use WESORT color sorter to accurately remove those hazelnuts that are completely moldy and black. If these moldy hazelnuts are mixed into the subsequent processing links, it will not only affect the quality and taste of the product, but also pose a potential threat to the health of consumers. Therefore, this step is crucial to ensure the quality of hazelnut raw materials.

4. Manual selection:

Although the color sorter has a high sorting accuracy, manual selection is still indispensable. With rich experience and keen observation, workers carefully select hazelnuts and remove those hazelnuts that may be missed by the color sorter, such as those that are slightly damaged, irregular in shape or slightly abnormal in color, to further improve the quality of the raw materials.

1. Water washing and peeling:

The hazelnuts are peeled by gentle water washing. This method can effectively remove the outer skin of the hazelnuts without damaging the hazelnut kernels, making the hazelnuts present a more attractive appearance and taste, and also provides a purer raw material basis for subsequent processing steps.

2. Peeling by color sorter:

Use the WESORT color sorter to screen the peeled hazelnuts to ensure the consistency of the peeling effect and the stability of the quality of the hazelnuts. Through the precise identification and sorting of the color sorter, those hazelnuts with incomplete peeling, uneven color or other impurities can be removed to ensure the high quality of the hazelnuts entering the next process.

1. Drying:

Dry the hazelnuts to reduce their moisture content, extend the shelf life and improve the taste. However, it should be noted that the dried hazelnuts become more fragile, which requires extra care in the subsequent processing and transportation, and take corresponding protective measures, such as using soft containers and cushioning materials to reduce the breakage rate of hazelnuts.

2. Sorting:

Good products (little or no skin):

At this stage, carefully select hazelnuts with little or no skin as good products. These hazelnuts usually have better appearance and taste, which better meet the market demand for high-quality hazelnuts and can bring consumers a better eating experience, thereby improving the market competitiveness of products.

Defective products (with skin, shell, moldy, etc.):

Hazelnuts with serious skin, shell residue, mold, stones or branches are classified as defective. If these defective hazelnuts are mixed into the finished product, it will seriously affect the quality and reputation of the product. Therefore, they must be strictly distinguished to prevent them from entering the market circulation link.

Re-roasting and selection:

For those hazelnuts judged as defective, they are re-roasted and then selected again. Re-roasting can further remove moisture and possible odors from hazelnuts. At the same time, through re-sorting, it can further distinguish unqualified products such as those with severe skin, shell, mold, stone, branches, etc. from relatively good hazelnuts, improve the utilization rate of raw materials, and reduce production costs.

Good products after re-roasting (without skin):

After re-roasting and re-sorting, hazelnuts without skin are selected as good products. Although these hazelnuts have undergone additional processing steps, they still have high quality and can be processed with other good hazelnuts for subsequent processing, ensuring the stability of raw material quality throughout the production process and reducing waste.

In the entire hazelnut processing process, each step is closely linked and indispensable. Through a series of operations such as reasonable rough processing, peeling processing, drying and sorting, and fully combining advanced WESORT color sorting machine technology and meticulous manual sorting, it can ensure the production of high-quality hazelnut products to meet the market demand for high-quality hazelnuts.

In modern agriculture, food processing, and recycling, quality control plays a vital role. This is where an optical sorter comes in. Many buyers often ask: What is an optical sorter? What does it do? How much does it cost? And how is WESORT optical...

In the coffee industry, the quality of the final cup often depends on the smallest details during processing. One crucial step is removing defective beans, foreign materials, and color inconsistencies. This is where a coffee bean color sorter plays...

Coffee processing is a complex and meticulous task that involves several stages to transform raw coffee cherries into the high-quality beans we enjoy in our morning brew. One crucial step in this process is the sorting of coffee beans based on thei...

In the world of walnut processing, even the smallest imperfection can significantly impact product quality, market price, and brand reputation. Mold, insect damage, broken pieces, or inconsistent color are common defects that reduce the value of wa...

From green bean exporters to specialty coffee roasters, every producer faces the same challenge: how to remove defects efficiently while protecting valuable beans. Problems such as mold, fermentation damage, insect bites, black beans, broken beans,...

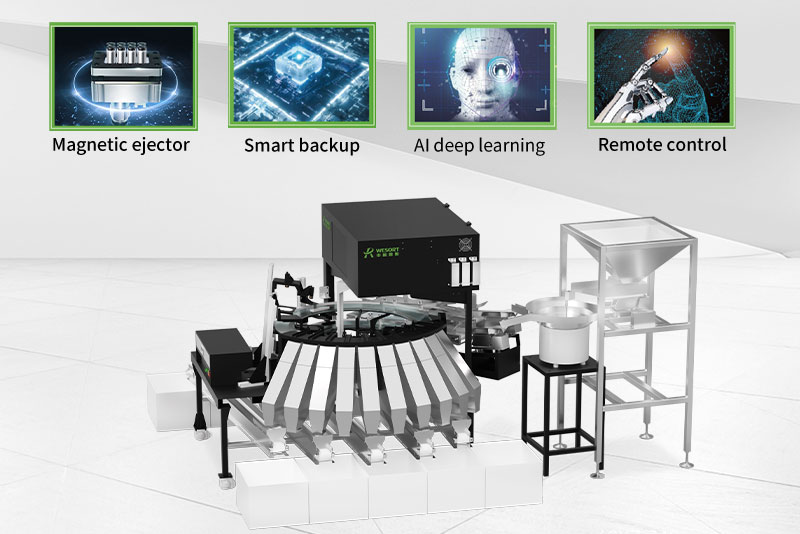

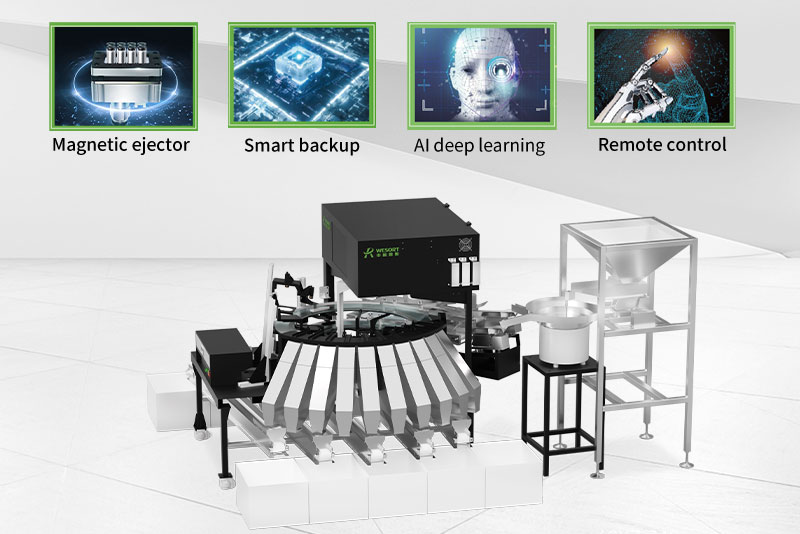

To meet the growing demand for premium and specialty coffee, sorting accuracy must go beyond traditional color-based systems. The QuadEye 360 AI Coffee Bean Sorter, developed by WESORT, represents the next generation of intelligent coffee bean so...

Dear friend, If you are attending World of Coffee Dubai 2026. we would like to invite you to visit WESORT. We will showcase our QuadEye 360 AI Coffee Bean Sorter, featuring 360° four-side inspection, AI deep learning models, near-zero breakage,...

Meta Description: Looking for the top hazelnut sorting machine manufacturer? WESORT offers advanced hazelnut color sorters with AI deep learning to efficiently remove defects, pests, and foreign materials. Boost your hazelnut processing efficienc...

With the growing popularity of specialty coffee, the purity of coffee beans determines the aroma and taste of a cup of coffee. Achieving 99.9% purity requires high-performance coffee bean sorting equipment. Among Chinese coffee bean color sorter ma...

What's the most vexing issue in the hazelnut industry chain? It's not yield, but quality. Defects like mold, wrinkled skin, and foreign matter not only reduce product value but can also put export orders at risk. The solution isn't to increase the ...

Every hazelnut tells a story—about the soil it grew in, the care during harvest, and the precision of its processing. Yet between farm and final product, hidden defects like mold, insect damage, and discoloration can turn premium hazelnuts into cos...

Plastic waste recycling is one of the most pressing challenges in today’s sustainability-driven world. Proper plastic sorting ensures high-quality recycled materials, reduces environmental impact, and improves profitability for recycling businesses...

In the plastic recycling industry, purity and efficiency directly determine profitability. As global demand for recycled plastics increases, manufacturers need advanced solutions to separate impurities, improve yield, and ensure consistent product ...

In Mexico, coffee is more than just a drink — it’s a culture, a tradition, and a vital industry. Yet, challenges like impurities, pest damage, and uneven coloration often diminish the value of even the most carefully cultivated beans. At EXPO CAFÉ...

The global demand for hazelnuts continues to rise, driven by the growth of confectionery, bakery, and healthy snack markets. As consumption increases, so does the importance of quality control. Hazelnut processors face mounting pressure to deliver ...

Hazelnuts are widely used in confectionery, bakery, and snacks, where product quality directly affects market value. However, hazelnut processing often faces serious challenges, such as pest infestation, seasonal labor shortages, and inconsistent m...

Hazelnut is the nut of the hazel and therefore includes any of the nuts deriving from species of the genus Corylus, especially the nuts of the species Corylus avellana. It is also known as cobnut or filbert nut according to species. A cob is roughl...

When you enjoy a smooth cup of coffee, you may not realize how much work goes into ensuring its purity and flavor. From harvest to cup, every step matters—and one of the most critical yet often overlooked stages is coffee bean sorting. Common Cof...

Dear Coffee Industry Partners, The Mexican Coffee Shop Expo 2025 is just around the corner—and WESORT , a leader in intelligent sorting technology, will be there to showcase our core solution for coffee processors: Coffee Bean Color Sorters. Mark...

In the plastic pellet production process, color purity often directly determines the product's selling price and market competitiveness. Especially for transparent, white, or light-colored plastic pellets, even tiny black specks can affect the appe...

In modern agriculture, food processing, and recycling, quality control plays a vital role. This is where an optical sorter comes in. Many buyers often ask: What is an optical sorter? What does it do? How much does it cost? And how is WESORT optical...

In the coffee industry, the quality of the final cup often depends on the smallest details during processing. One crucial step is removing defective beans, foreign materials, and color inconsistencies. This is where a coffee bean color sorter plays...

Coffee processing is a complex and meticulous task that involves several stages to transform raw coffee cherries into the high-quality beans we enjoy in our morning brew. One crucial step in this process is the sorting of coffee beans based on thei...

In the world of walnut processing, even the smallest imperfection can significantly impact product quality, market price, and brand reputation. Mold, insect damage, broken pieces, or inconsistent color are common defects that reduce the value of wa...

From green bean exporters to specialty coffee roasters, every producer faces the same challenge: how to remove defects efficiently while protecting valuable beans. Problems such as mold, fermentation damage, insect bites, black beans, broken beans,...

To meet the growing demand for premium and specialty coffee, sorting accuracy must go beyond traditional color-based systems. The QuadEye 360 AI Coffee Bean Sorter, developed by WESORT, represents the next generation of intelligent coffee bean so...

Dear friend, If you are attending World of Coffee Dubai 2026. we would like to invite you to visit WESORT. We will showcase our QuadEye 360 AI Coffee Bean Sorter, featuring 360° four-side inspection, AI deep learning models, near-zero breakage,...

Meta Description: Looking for the top hazelnut sorting machine manufacturer? WESORT offers advanced hazelnut color sorters with AI deep learning to efficiently remove defects, pests, and foreign materials. Boost your hazelnut processing efficienc...