Shenzhen Wesort Optoelectronics Co., Ltd.

Address:Building 29, Longwangmiao Industrial Zone, Fuyong street, Bao'an District, Shenzhen, Guangdong Province, China.

Phone:+86 181 2370 6862

In the nut processing industry, the nut color sorter is playing a crucial role. It is not only a key link in ensuring food safety but also an important means to achieve high-quality and consistent products.

I. The Importance and Principle of Optical Sorting

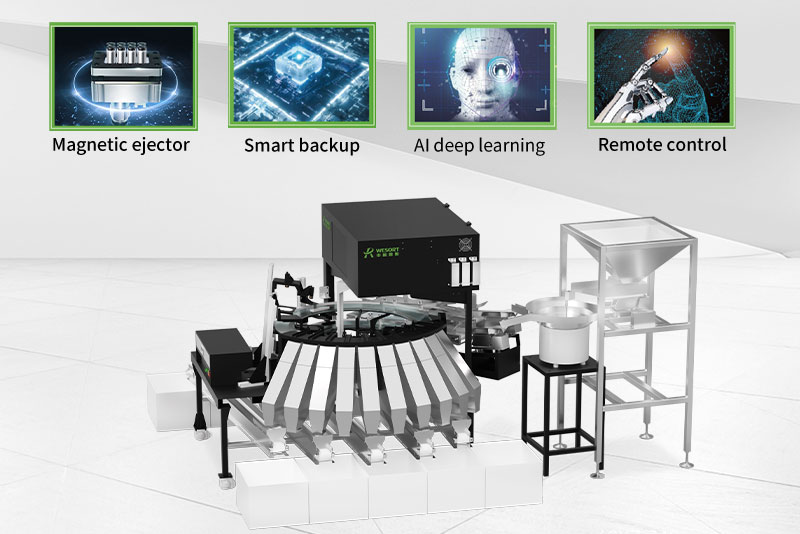

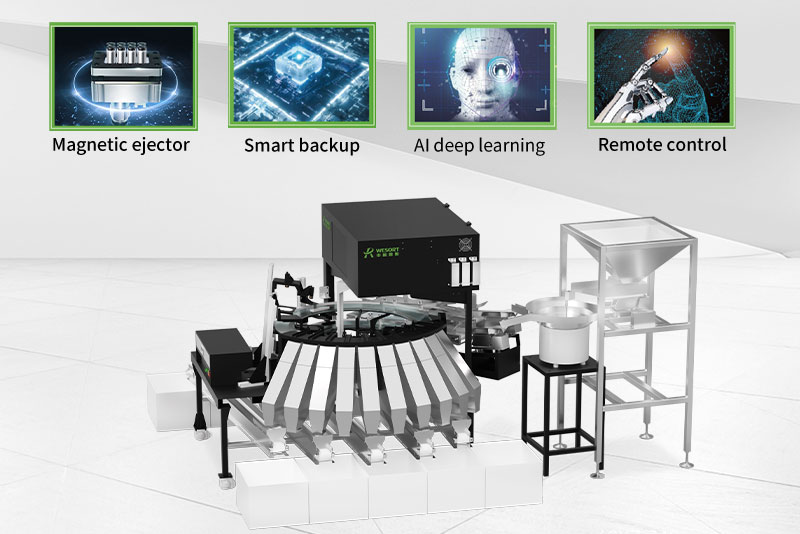

Optical sorting is essential in any nut processing operation. It utilizes a series of advanced technologies, including high-precision cameras, intelligent lighting systems, and advanced machine learning software, to accurately identify and remove product defects and foreign materials based on the color, shape, and texture of nuts. By doing so, it ensures the purity and safety of nut products and meets consumers' demands for high-quality nuts. Whether it is tiny impurities hidden within the nuts or barely noticeable color blemishes on the surface, the color sorter can sensitively detect and eliminate them, thus providing consumers with reliable and high-quality nut products.

II. Wide Range of Product Applications

We offer a diverse range of nut color sorters to meet different nut varieties and processing requirements.

(I) Almond Sorting

For almond processors, our nut color sorter is an ideal choice for achieving high standards in producing safe, clean, and consistently high-quality almond products, including in-shell, natural, or blanched almonds. It can effectively remove various defects and ensure the outstanding quality of almond products.

(II) Hazelnut Sorting

WESORT's optical sorting technology can sort different grades and types of hazelnuts, such as natural, blanched, and roasted hazelnuts. It can efficiently remove color defects like dark, discolored, shriveled, and rotten hazelnuts, as well as foreign materials like shells, wood, and sticks, delivering a safe and flawless end product.

(III) Cashew Sorting

WESORT's optical sorting technology is applicable to various grades and stages of cashew nuts, including whole, split, chopped/diced, raw, or roasted cashews. It can effectively remove common defects such as cashews with slight discoloration or dark spots, sticks, stones, and shells, and even challenging defects like rotten pieces in diced/chopped cashews, providing a reliable quality assurance for cashew processing.

(IV) Walnut Sorting

WESORT's optical sorting technology offers walnut processors the flexibility to sort different varieties and grades of walnuts, such as in-shell and shelled walnuts, including sizes ranging from halves to double-diced and colors ranging from extra light to amber. It can remove discolored, shriveled, moldy, or insect-damaged walnuts, butterballs, as well as challenging foreign materials such as septa/membrane and shell, ensuring the high quality of walnut products.

(V) Macadamia Sorting

WESORT's optical sorting technology provides macadamia nut processors with the flexibility to sort different varieties and grades of macadamia nuts, including in-shell, whole, halves, and pieces. It can remove typical defects found in macadamia nuts, such as shell pieces, in-shell nuts, discolored, rotten, and insect-damaged nuts caused by stink bugs, safeguarding the quality and safety of macadamia nuts.

(VI) Peanut Sorting

WESORT's optical sorting technology can sort different varieties of peanuts, including in-shell (Spanish or Valencia's) with red or pink skin, blanched, or roasted peanuts. It can efficiently remove defects with certain discolorations, in-shell, split, oversized/undersized, or misshaped peanuts, as well as foreign materials, including sticks and bones.

(VII) Pecan Sorting

WESORT's optical sorting technology offers pecan processors the flexibility to sort different varieties and grades of pecans, such as in-shell and shelled pecans, including sizes ranging from halves to pieces and colors ranging from light to dark amber. It can remove discolored, insect-damaged, moldy, or immature kernels, as well as foreign materials, including sticks, septa/membrane, and shells.

(VIII) Pine Nut Sorting

Our nut color sorter is the preferred choice for pine nut processors. It can efficiently remove defects, including rotten pieces and discolored pine kernels, as well as foreign materials such as shells, sticks, and stones, ensuring the quality and purity of pine nut products.

(IX) Pistachio Sorting

WESORT's optical sorting technology can sort in-shell or shelled pistachios in raw or roasted states. It can efficiently remove typical defects such as light or dark stained shells, insect-damaged, moldy decayed, shriveled, broken, or oversized/undersized in-shell pistachios or kernels, as well as foreign materials, including shell pieces, sticks, rocks, and loose kernels from in-shell nuts.

(X) Brazil Nut Sorting

Equipped with the latest technological advances, the WESORT optical sorters are able to effectively remove both typical and challenging color defects, including shape recognition of damaged pieces, broken bits, sticks, stones, insects, and various other packing materials, ensuring the high quality of Brazil nuts.

III. Product Advantages and Customized Services

Our nut color sorters not only have a wide range of applications but also offer numerous advantages. Additionally, we provide customized solutions based on factors such as customers' budgets, production capacities, and desired product qualities, ensuring that each customer can find the most suitable equipment. Whether it is a large processing plant aiming for high production volume or a boutique producer focusing on product quality, we can meet their needs and help them stand out in the nut market and achieve sustainable development.

In conclusion, our optical sorting solutions for nuts, with advanced technology, wide application range, and outstanding product advantages, provide comprehensive quality assurance for the nut processing industry. In the pursuit of food safety and high-quality products today, we will continue to focus on innovation and optimization of optical sorting technology to provide customers with better and more efficient services and jointly promote the development of the nut industry.

In the nut processing industry, the nut color sorter is playing a crucial role. It is not only a key link in ensuring food safety but also an important means to achieve high-quality and consistent products.

I. The Importance and Principle of Optical Sorting

Optical sorting is essential in any nut processing operation. It utilizes a series of advanced technologies, including high-precision cameras, intelligent lighting systems, and advanced machine learning software, to accurately identify and remove product defects and foreign materials based on the color, shape, and texture of nuts. By doing so, it ensures the purity and safety of nut products and meets consumers' demands for high-quality nuts. Whether it is tiny impurities hidden within the nuts or barely noticeable color blemishes on the surface, the color sorter can sensitively detect and eliminate them, thus providing consumers with reliable and high-quality nut products.

II. Wide Range of Product Applications

We offer a diverse range of nut color sorters to meet different nut varieties and processing requirements.

(I) Almond Sorting

For almond processors, our nut color sorter is an ideal choice for achieving high standards in producing safe, clean, and consistently high-quality almond products, including in-shell, natural, or blanched almonds. It can effectively remove various defects and ensure the outstanding quality of almond products.

(II) Hazelnut Sorting

WESORT's optical sorting technology can sort different grades and types of hazelnuts, such as natural, blanched, and roasted hazelnuts. It can efficiently remove color defects like dark, discolored, shriveled, and rotten hazelnuts, as well as foreign materials like shells, wood, and sticks, delivering a safe and flawless end product.

(III) Cashew Sorting

WESORT's optical sorting technology is applicable to various grades and stages of cashew nuts, including whole, split, chopped/diced, raw, or roasted cashews. It can effectively remove common defects such as cashews with slight discoloration or dark spots, sticks, stones, and shells, and even challenging defects like rotten pieces in diced/chopped cashews, providing a reliable quality assurance for cashew processing.

(IV) Walnut Sorting

WESORT's optical sorting technology offers walnut processors the flexibility to sort different varieties and grades of walnuts, such as in-shell and shelled walnuts, including sizes ranging from halves to double-diced and colors ranging from extra light to amber. It can remove discolored, shriveled, moldy, or insect-damaged walnuts, butterballs, as well as challenging foreign materials such as septa/membrane and shell, ensuring the high quality of walnut products.

(V) Macadamia Sorting

WESORT's optical sorting technology provides macadamia nut processors with the flexibility to sort different varieties and grades of macadamia nuts, including in-shell, whole, halves, and pieces. It can remove typical defects found in macadamia nuts, such as shell pieces, in-shell nuts, discolored, rotten, and insect-damaged nuts caused by stink bugs, safeguarding the quality and safety of macadamia nuts.

(VI) Peanut Sorting

WESORT's optical sorting technology can sort different varieties of peanuts, including in-shell (Spanish or Valencia's) with red or pink skin, blanched, or roasted peanuts. It can efficiently remove defects with certain discolorations, in-shell, split, oversized/undersized, or misshaped peanuts, as well as foreign materials, including sticks and bones.

(VII) Pecan Sorting

WESORT's optical sorting technology offers pecan processors the flexibility to sort different varieties and grades of pecans, such as in-shell and shelled pecans, including sizes ranging from halves to pieces and colors ranging from light to dark amber. It can remove discolored, insect-damaged, moldy, or immature kernels, as well as foreign materials, including sticks, septa/membrane, and shells.

(VIII) Pine Nut Sorting

Our nut color sorter is the preferred choice for pine nut processors. It can efficiently remove defects, including rotten pieces and discolored pine kernels, as well as foreign materials such as shells, sticks, and stones, ensuring the quality and purity of pine nut products.

(IX) Pistachio Sorting

WESORT's optical sorting technology can sort in-shell or shelled pistachios in raw or roasted states. It can efficiently remove typical defects such as light or dark stained shells, insect-damaged, moldy decayed, shriveled, broken, or oversized/undersized in-shell pistachios or kernels, as well as foreign materials, including shell pieces, sticks, rocks, and loose kernels from in-shell nuts.

(X) Brazil Nut Sorting

Equipped with the latest technological advances, the WESORT optical sorters are able to effectively remove both typical and challenging color defects, including shape recognition of damaged pieces, broken bits, sticks, stones, insects, and various other packing materials, ensuring the high quality of Brazil nuts.

III. Product Advantages and Customized Services

Our nut color sorters not only have a wide range of applications but also offer numerous advantages. Additionally, we provide customized solutions based on factors such as customers' budgets, production capacities, and desired product qualities, ensuring that each customer can find the most suitable equipment. Whether it is a large processing plant aiming for high production volume or a boutique producer focusing on product quality, we can meet their needs and help them stand out in the nut market and achieve sustainable development.

In conclusion, our optical sorting solutions for nuts, with advanced technology, wide application range, and outstanding product advantages, provide comprehensive quality assurance for the nut processing industry. In the pursuit of food safety and high-quality products today, we will continue to focus on innovation and optimization of optical sorting technology to provide customers with better and more efficient services and jointly promote the development of the nut industry.

In modern agriculture, food processing, and recycling, quality control plays a vital role. This is where an optical sorter comes in. Many buyers often ask: What is an optical sorter? What does it do? How much does it cost? And how is WESORT optical...

In the coffee industry, the quality of the final cup often depends on the smallest details during processing. One crucial step is removing defective beans, foreign materials, and color inconsistencies. This is where a coffee bean color sorter plays...

Coffee processing is a complex and meticulous task that involves several stages to transform raw coffee cherries into the high-quality beans we enjoy in our morning brew. One crucial step in this process is the sorting of coffee beans based on thei...

In the world of walnut processing, even the smallest imperfection can significantly impact product quality, market price, and brand reputation. Mold, insect damage, broken pieces, or inconsistent color are common defects that reduce the value of wa...

From green bean exporters to specialty coffee roasters, every producer faces the same challenge: how to remove defects efficiently while protecting valuable beans. Problems such as mold, fermentation damage, insect bites, black beans, broken beans,...

To meet the growing demand for premium and specialty coffee, sorting accuracy must go beyond traditional color-based systems. The QuadEye 360 AI Coffee Bean Sorter, developed by WESORT, represents the next generation of intelligent coffee bean so...

Dear friend, If you are attending World of Coffee Dubai 2026. we would like to invite you to visit WESORT. We will showcase our QuadEye 360 AI Coffee Bean Sorter, featuring 360° four-side inspection, AI deep learning models, near-zero breakage,...

Meta Description: Looking for the top hazelnut sorting machine manufacturer? WESORT offers advanced hazelnut color sorters with AI deep learning to efficiently remove defects, pests, and foreign materials. Boost your hazelnut processing efficienc...

With the growing popularity of specialty coffee, the purity of coffee beans determines the aroma and taste of a cup of coffee. Achieving 99.9% purity requires high-performance coffee bean sorting equipment. Among Chinese coffee bean color sorter ma...

What's the most vexing issue in the hazelnut industry chain? It's not yield, but quality. Defects like mold, wrinkled skin, and foreign matter not only reduce product value but can also put export orders at risk. The solution isn't to increase the ...

Every hazelnut tells a story—about the soil it grew in, the care during harvest, and the precision of its processing. Yet between farm and final product, hidden defects like mold, insect damage, and discoloration can turn premium hazelnuts into cos...

Plastic waste recycling is one of the most pressing challenges in today’s sustainability-driven world. Proper plastic sorting ensures high-quality recycled materials, reduces environmental impact, and improves profitability for recycling businesses...

In the plastic recycling industry, purity and efficiency directly determine profitability. As global demand for recycled plastics increases, manufacturers need advanced solutions to separate impurities, improve yield, and ensure consistent product ...

In Mexico, coffee is more than just a drink — it’s a culture, a tradition, and a vital industry. Yet, challenges like impurities, pest damage, and uneven coloration often diminish the value of even the most carefully cultivated beans. At EXPO CAFÉ...

The global demand for hazelnuts continues to rise, driven by the growth of confectionery, bakery, and healthy snack markets. As consumption increases, so does the importance of quality control. Hazelnut processors face mounting pressure to deliver ...

Hazelnuts are widely used in confectionery, bakery, and snacks, where product quality directly affects market value. However, hazelnut processing often faces serious challenges, such as pest infestation, seasonal labor shortages, and inconsistent m...

Hazelnut is the nut of the hazel and therefore includes any of the nuts deriving from species of the genus Corylus, especially the nuts of the species Corylus avellana. It is also known as cobnut or filbert nut according to species. A cob is roughl...

When you enjoy a smooth cup of coffee, you may not realize how much work goes into ensuring its purity and flavor. From harvest to cup, every step matters—and one of the most critical yet often overlooked stages is coffee bean sorting. Common Cof...

Dear Coffee Industry Partners, The Mexican Coffee Shop Expo 2025 is just around the corner—and WESORT , a leader in intelligent sorting technology, will be there to showcase our core solution for coffee processors: Coffee Bean Color Sorters. Mark...

In the plastic pellet production process, color purity often directly determines the product's selling price and market competitiveness. Especially for transparent, white, or light-colored plastic pellets, even tiny black specks can affect the appe...

In modern agriculture, food processing, and recycling, quality control plays a vital role. This is where an optical sorter comes in. Many buyers often ask: What is an optical sorter? What does it do? How much does it cost? And how is WESORT optical...

In the coffee industry, the quality of the final cup often depends on the smallest details during processing. One crucial step is removing defective beans, foreign materials, and color inconsistencies. This is where a coffee bean color sorter plays...

Coffee processing is a complex and meticulous task that involves several stages to transform raw coffee cherries into the high-quality beans we enjoy in our morning brew. One crucial step in this process is the sorting of coffee beans based on thei...

In the world of walnut processing, even the smallest imperfection can significantly impact product quality, market price, and brand reputation. Mold, insect damage, broken pieces, or inconsistent color are common defects that reduce the value of wa...

From green bean exporters to specialty coffee roasters, every producer faces the same challenge: how to remove defects efficiently while protecting valuable beans. Problems such as mold, fermentation damage, insect bites, black beans, broken beans,...

To meet the growing demand for premium and specialty coffee, sorting accuracy must go beyond traditional color-based systems. The QuadEye 360 AI Coffee Bean Sorter, developed by WESORT, represents the next generation of intelligent coffee bean so...

Dear friend, If you are attending World of Coffee Dubai 2026. we would like to invite you to visit WESORT. We will showcase our QuadEye 360 AI Coffee Bean Sorter, featuring 360° four-side inspection, AI deep learning models, near-zero breakage,...

Meta Description: Looking for the top hazelnut sorting machine manufacturer? WESORT offers advanced hazelnut color sorters with AI deep learning to efficiently remove defects, pests, and foreign materials. Boost your hazelnut processing efficienc...